- +86-18606286868 | +86-512-58138883

- sales@elantmachine.com

This document serves as a professional technical guide for industrial Solid State Polymerization (SSP) systems, focusing on the core function of upgrading PET (Polyethylene Terephthalate) material performance. It details modular configurations, technical parameters, and application value, tailored for high-end PET production scenarios such as bottle-grade, fiber-grade, and sheet-grade recycling and processing.

Solid State Polycondensation Plant for high-viscosity PET production.

SSP system for high-quality bottle-grade PET production.

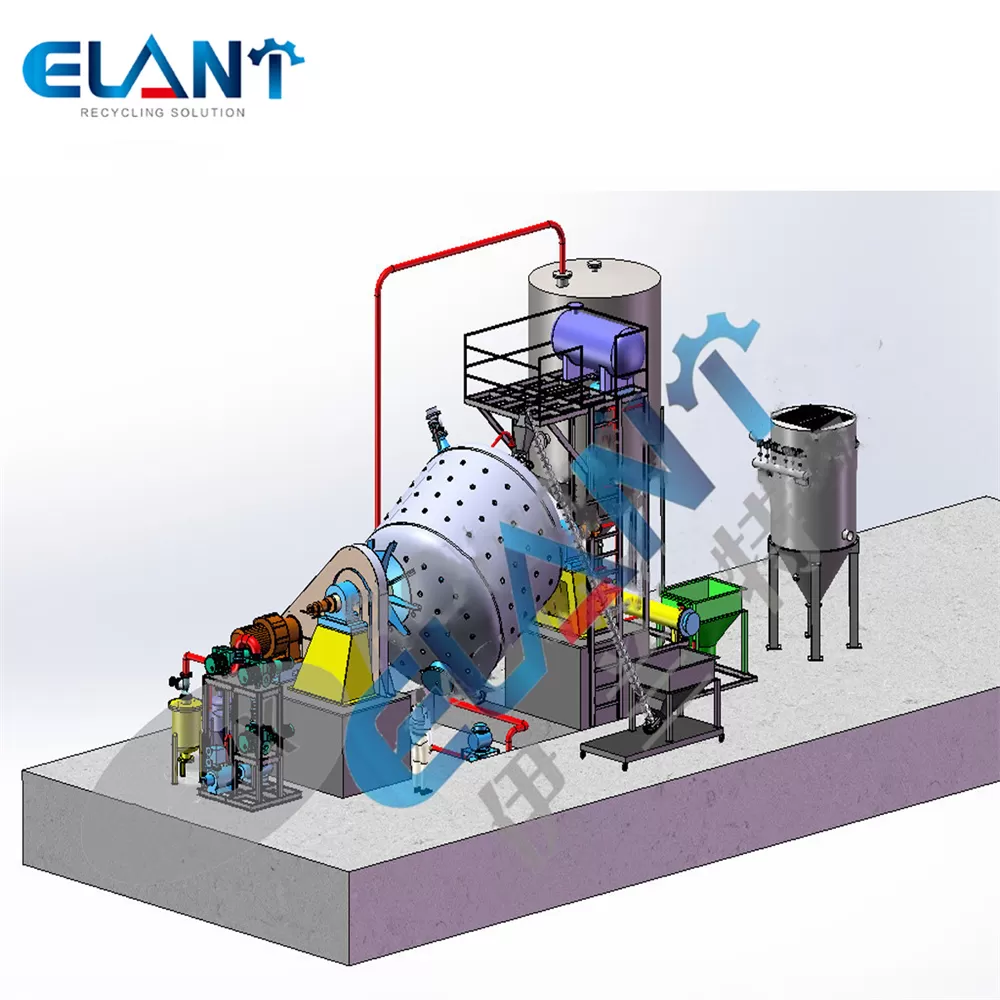

Polyester chip tumble dryer for SSP pre-drying.

A Solid State Polycondensation (SSP) Plant is designed to increase the intrinsic viscosity and molecular weight of amorphous PET chips through controlled thermal treatment in an inert (typically nitrogen) or vacuum environment. The process involves pre-crystallization, drying, and polycondensation at temperatures below the melting point but above the glass transition point, enabling chain extension without melting. Widely used in bottle, film, and industrial fiber manufacturing, SSP plants produce high-quality rPET or virgin PET with enhanced mechanical and thermal properties, meeting stringent food-grade or engineering-grade standards.

The ML180 Cutter Compactor is a compact, high-efficiency granulator designed for processing PP, PE, and LDPE plastic films—such as shopping bags, shrink wrap, and packaging scraps. It combines cutting and densification in one step, turning lightweight, bulky film into dense, free-flowing flakes ideal for direct feeding into extruders or washing lines. Featuring robust blades, low noise operation, and a capacity of 100–150 kg/h, the ML180 offers reliable pre-processing for small to medium-scale recycling operations.

The Polyester Chip Tumble Dryer is a critical component in the Solid State Polycondensation (SSP) system, designed to thoroughly dry polyester (PET) chips before crystallization and polycondensation. Using heated, dehumidified air in a rotating drum, it ensures uniform moisture removal—typically reducing water content to below 50 ppm—without causing particle agglomeration or thermal degradation. This pre-drying step is essential for stable SSP performance, as residual moisture can hydrolyze PET chains during high-temperature processing. The tumble dryer’s gentle agitation, corrosion-resistant construction, and precise temperature control make it ideal for both virgin and recycled bottle-grade PET chip preparation.

| Sub-module Name | Core Composition | Core Functions |

|---|---|---|

| Feeding & Metering Module | Screw feeder with frequency conversion, anti-bridging hopper, material level sensor | Uniform and continuous feeding of pre-dried PET materials; precise metering to match reactor load |

| Gradient Pre-Heating Module | Insulated pre-heater, multi-point temperature sensors, nitrogen pre-heating unit | Gradually heats PET to the SSP reaction temperature range (200–225°C); avoids thermal shock to materials |

| SSP Reactor Module | Vertical/tubular reactor, multi-zone heating jacket, residence time adjustment mechanism | Core reaction unit; provides stable temperature and inert atmosphere for PET solid-state polycondensation |

| Nitrogen Purification & Recycling Module | Oligomer filter, molecular sieve moisture absorber, nitrogen compressor, purity sensor | Purifies nitrogen containing oligomers and moisture; recycles nitrogen to ensure inert atmosphere stability and reduce consumption |

| Gradient Cooling Module | Water-cooled cooler, air-cooled buffer section, closed-loop conveyor | Gradually cools high-IV PET to ≤50°C (safe handling temperature); prevents material agglomeration |

| Central Control Module | PLC controller, HMI touch screen, safety interlock system, data logging unit | Integrates control of all modules; real-time monitoring of key parameters (temperature, pressure, IV, nitrogen purity); automatic fault alarm and data traceability |

Multi-zone temperature regulation, 4–10h adjustable residence time, online IV monitoring; control accuracy ±0.02 dL/g.

Closed-loop circulation, purity ≥99.99%, oxygen <50 ppm; cuts nitrogen usage by 35%, avoids PET oxidation.

Waste heat recovery, frequency-conversion blowers; unit energy consumption ≤1.2 kWh/kg, 20% lower than conventional models.

No VOC/wastewater discharge; recyclable oligomer by-products; meets EU REACH & US FDA standards.

High-speed centrifugal dewatering removes ~90% surface moisture, followed by hot-air drying to ≤0.5% moisture—ideal for direct pelletizing or storage without mold risk.

Uniform molecular weight distribution; low product performance fluctuation; qualification rate ≥99%.

| Technical Indicator | Specification Range | Description |

|---|---|---|

| Processing Capacity | 50–3000 kg/h | Customizable according to production scale; supports modular expansion |

| SSP Reaction Temperature | 200–225°C (adjustable) | Below PET melting point; avoids material melting |

| Residence Time | 4–10 hours (adjustable) | Longer time for higher target IV; precise control via material conveying speed |

| Initial IV of Input Material | 0.60–0.72 dL/g | Standard input range for recycled/virgin low-IV PET |

| Target IV of Finished Product | 0.78–0.85 dL/g (bottle-grade); ≥0.90 dL/g (fiber-grade) | Meets industry standards for different high-end applications |

| Nitrogen Purity | ≥99.99% | Ensures inert atmosphere; prevents PET oxidation |

| Oxygen Content in Reactor | <50 ppm | Controlled by closed-loop nitrogen system |

| Unit Energy Consumption | ≤1.2 kWh/kg (finished product) | Based on heat recovery system; varies with processing capacity |

| Overall Dimensions (Standard Model) | 6.5m×3.2m×5.5m (L×W×H) | Industrial standard footprint; customizable for workshop layout |

| Power Supply | 380V/3Ph/50Hz | Compatible with global industrial power grids (customizable to 415V/60Hz) |

| Certifications | CE, ISO 9001, SGS, FDA (food-contact compliant) | Complies with international safety, quality and food contact standards |

Upgrades low-IV PET to bottle/fiber grade; increases added value by 30–50%.

35% less nitrogen consumption; 20% lower energy costs; 40% reduced labor input.

Precise IV control; ≤1% scrap rate; consistent performance for high-end applications.

Alloy core components; 12+ years lifespan; low maintenance frequency.

Pre-sales planning, on-site commissioning, 24h technical service; global logistics support.

Enables recycled PET to meet food-contact standards; accesses high-end textile/packaging markets.